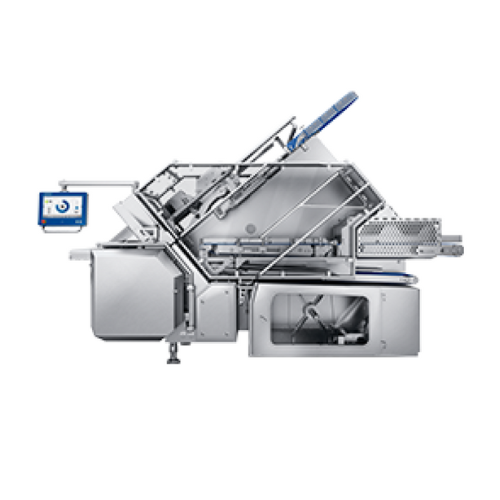

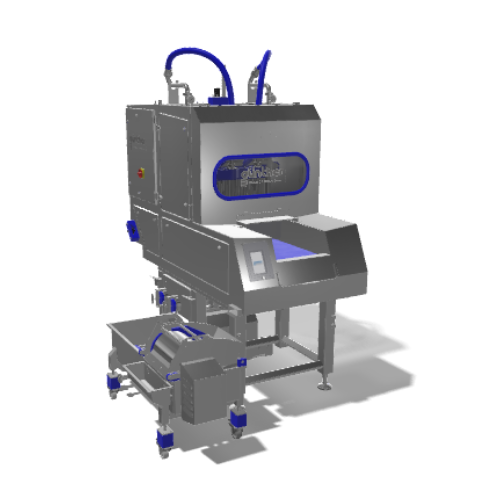

The PI 365-54/75/105 is a high-performance food injection machine, designed for efficient and precise brine distribution. It boasts a conveyor belt dimension of 365 mm, capable of moving 4052 kg/h of diverse materials like pork, beef, poultry, or cheese.

The equipment comes with a stainless steel centrifugal pump, and additional pumps can be made available for thicker viscosities upon request. The inclusion of a pre-filter mechanism to guard against needle blockage with electronic surveillance guarantees peak performance and extended equipment lifespan.

Special conveyor belts with foodstuff approval are used for hygienic and safe operation. The 1-fold, 2-fold, and 3-fold stitch adjustment via the control system allows for optimum brine distribution, tailored to the specific requirements of the product.

Technical data

| Belt width in mm | 365 |

| Needle designs | 54/75/105 |

| Capacity* in kg/h | 4052 |

| Product clearance in mm | 220 |

| Strokes in 1/minute | 50 |

| Dimensions in mm (length/width/height) | 1800/1000/2500 |

| Connection data | 6,5KW 16A 400V 3PH/N/PE |

| Compressed air | 6-8 bar |