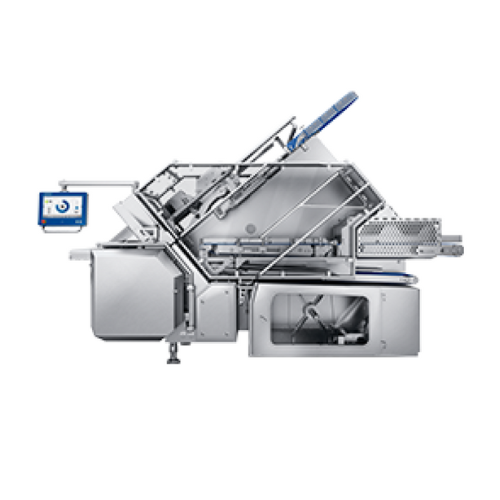

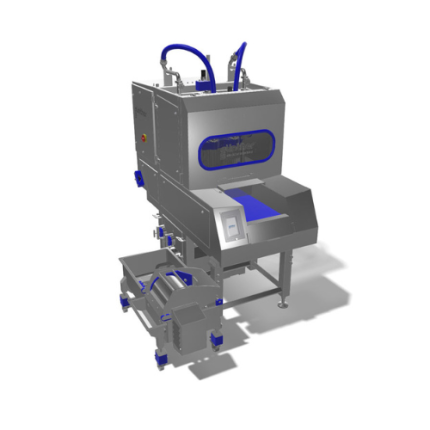

The Poly-Clip FCA 80 is a robust and reliable entry-level food clipping machine designed with robust and stainless steel construction, ensuring the highest reliability and long service life. Its basic-oriented operation allows for maximum productivity, making it an ideal solution for low to medium-volume production environments. The automatic double-clipper is capable of closing collagen casings up to 80 mm, fibrous casings up to 100 mm, and plastic casings up to 160 mm, depending on the material thickness. This machine is suitable for a range of calibres from 38 to 160 mm and can operate at up to 125 cycles per minute in continuous mode.

Technical data

Width |

1705 — 1800 Millimetre |

Height |

1995 — 2145 Millimetre |

Weight |

460 Kilogram |

Depth |

1030 Millimetre |

Three-phase current connection |

200 – 240 VAC, 380 – 460 VAC, 50/60 Hz |

Power input |

4 Kilowatt |

Fuse connection |

16 Ampere |

Compressed air |

5 — 7 bar |

Air consumption |

2.5 NL/Cycle |

Spreading |

26, 30, 36, 44 Millimetre |

Total spreading up to |

100 Millimetre |