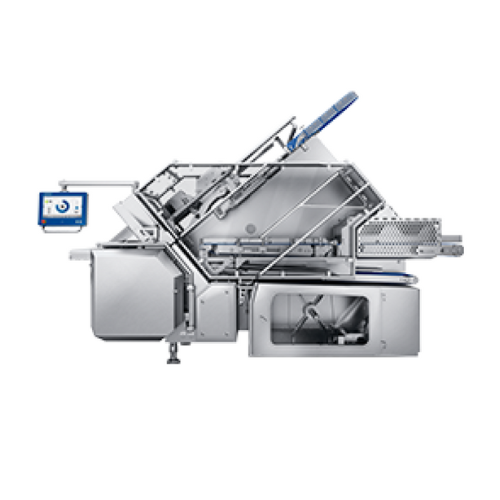

The ASB 600 by Weber is a belt derinder designed for artisanal and medium-sized companies, offering a wide range of applications and two processing speeds. It functions as a combination machine, open for round parts and closed with height-adjustable pressure rollers for flat parts, making it versatile for various meat processing tasks. The ASB 600 is suitable for derinding and membrane skinning, ensuring high yields in the meat processing industry. It is designed for open-top operation, making it ideal for processing rondelles, shoulders, and hocks. Additionally, it can be used for the gentle removal of skin from poultry parts. Its compact design and mobility via bock and rollers make it a space-saving solution for businesses seeking efficient and versatile meat processing equipment.

Technical data

| Motor output (kW) | 0.85 | |

| Power supply (V/Hz/A) | 400/50/16 | |

| Cutting width (mm) | 400 | |

| Slicing thickness (mm) | 0-4 | |

| length x width x height | 770 (with conveyor 1785) x 1200 x 1240 | |

| Others | Special voltage on request | |

| speed | variable |