Originating from Australia, Memstar offers a suite of methods designed to refine and enhance the taste of grape juice and wine. Their suite of services for wine alcohol adjustments encompasses the removal of undesirable flavours, alteration of the alcohol concentration in wine, reduction of its unstable acidity, and the implementation of heat treatment for the deactivation of laccase. Memstar’s offerings extend to alcohol adjustment, reduction of volatile acidity, taint minimisation, concentration of juice and wine, and heat processing to deactivate laccase. The firm provides a variety of strategies to boost the quality and attributes of alcoholic beverages, ranging from adjusting the alcohol volume to eliminating unwelcome compounds and concentrating the product.

The Unique new apprpach to wine alcohol adjustment

Go with the flow – the benefits of Memstar AA

Patented 2 stage membrane process preserves precious flavours, colour and tannin

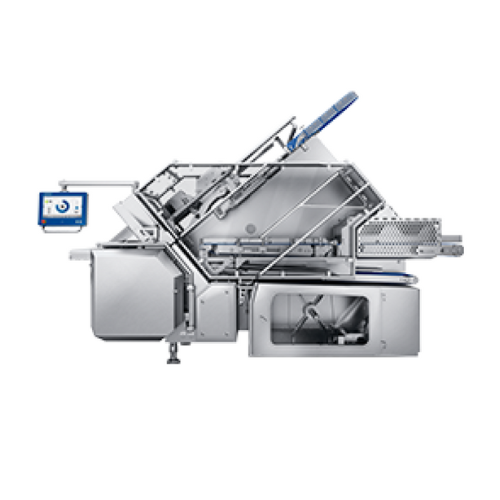

With the Memstar AA reverse osmosis and perstractive membrane process, wine alcohol is selectively reduced while flavours, colours and tannin are preserved.

The process is a “ closed loop “ with two membrane barriers between the wine being treated and the strip water which removes the alcohol.

The actual stripping step is performed on reserve osmosis permeate which contains very little of the precious wine characters that would otherwise be lost.

Wine quality maintained – no additions

The process is carried out in alcohol oxygen free environment and does not involve the addition of any extraneous material which dilutes wine flavours or otherwise degrades quality.

No water addition – no legal issues

The process does not involve the addition of water to wine – a practice which is not permitted in most wine producing countries. It also avoids the legally dubious addition of water from other grape sources.

No distillation – no regulatory issues

The process does not involve distillation ( high or low temperature ) with its substantial infrastructure and energy costs; also avoiding the taxation. OH&S and other regulatory issues associated with the production and handling of high strength alcoholic spirit.

Minimal volume loss

Virtually only alcohol is removed so the volume losses are minimal

Wine processed entirely on-site

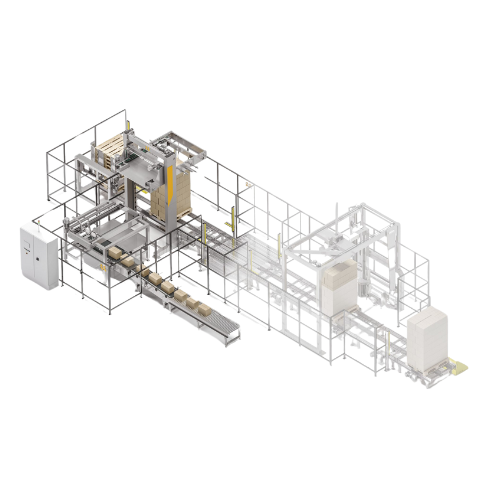

The whole process is performed on site by our skilled personnel using Memstar’s unique mobile equipment. No need for the wine nor the permeate to be shipped away for further processing.

Getting the alcohol right

To determine the optimum final alcohol level, the winemaker can perfom “sweet spot” trails at the commencement can stop. Then, monitoring progress, the winemaker can stop the process at the preferd alchol level.

Felxibility – service, hire or purchase

The Memstar AA alcohol adjustment process is available as a cost effective, on-site service provided by our skilled personnel