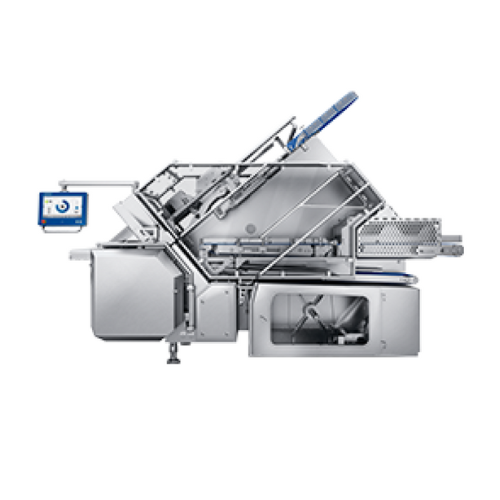

The Pall Oenoflow™ PRO XL-S systems are designed to meet the specific needs and requirements of mid-sized wineries, providing a cost-effective and sustainable alternative to traditional wine clarification methods. The filtration systems utilize Pall’s proven hollow fiber membranes, which are known for their mechanical strength and excellent chemical resistance.

Because of this, Oenoflow™ achieves clarification in a single process step, without the need for filter aids, centrifugation, or significant impact on the organoleptic characteristics of the wine. By increasing yields and reducing waste volumes, the fully automated systems provide a cost-saving and sustainable solution for wine clarification.

Technical data

| Model | No. of modules | Filter Area (m2) | Average flow rate2 | Length | Width | Height | Weight (empty) |

| Oenoflow XL-3S | 3 | 64.5 | 30 – 45 hl/h (790 – 1190 gph) |

2.60 m (8.53 ft) |

1.20 m (3.94 ft) |

2.15 m (7.05 ft) |

1420 kg (3130 lbs) |

| Oenoflow XL-4S | 4 | 86 | 40 – 60 hl/h (1050 – 1580 gph) |

2.70 m (8.86 ft) |

1.20 m (3.94 ft) |

2.15 m (7.05 ft) |

1550 kg (3417 lbs) |

| Oenoflow XL-5S | 5 | 107.5 | 50 – 75 hl/h (1320 – 1980 gph) |

3.00 m (9.84 ft) |

1.20 m (3.94 ft) |

2.15 m (7.05 ft) |

1590 kg (3505 lbs) |

| Oenoflow XL-6S | 6 | 129 | 60 – 90 hl/h (1580 – 2380 gap) |

3.00 m (9.84 ft) |

1.20 m (3.94 ft) |

2.15 m (7.05 ft) |

1690 kg (3725 lbs) |