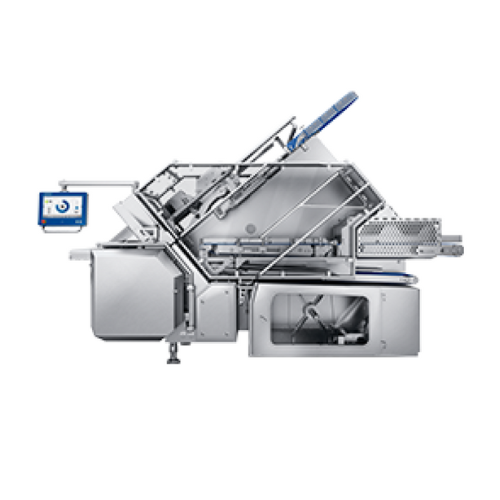

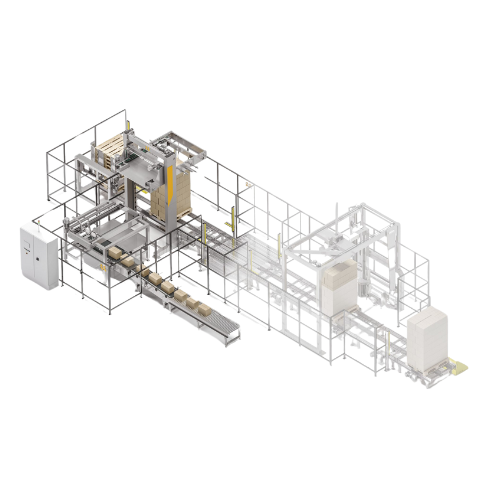

The MBF Monoblock delivers a compact, high-performance, and tailor-made solution for bottle-filling needs, crafted to cater to diverse industries. Its design incorporates a rinser, filler, and capper for cork and/or screw, all consolidated within one machine, effectively maximizing productivity while considerably cutting down on expenses and space.

Each component of the monobloc can be assembled either on a singular frame or an autonomous modular one, proffering the client optimal adaptability and autonomy for their current and future setup. The monobloc boasts a stainless steel foundation featuring slanted surfaces that enhance the sanitation of the surfaces. Additionally, it comes with fully clear safety shields, facilitating easy visual access and effortless reach to all parts of the machine.

MBF monoblock is the combination of rinser, filler, corker and/or screw capper in a single machine.

Each machine of the monoblock can be fitted on a single frame or on an independent modular frame: this kind of solution offers our customers maximum flexibility.

The monoblock can be supplied with stainless steel base with inclined surfaces to improve cleanliness, and it is equipped with totally transparent safety covers which provide easy vision and access to all machine sections.

The monoblock technology is designed to provide an outstanding processing versatility with any bottle and cap format. The format change is performed through the control of the servo motorised screws or, alternatively, by means of the tine transfer system and the automatic universal stars patented by MBF. Further distinctive features of MBF: error-free processing thanks to the automatic setup of each format, user-friendliness and minimised maintenance for the whole monoblock.