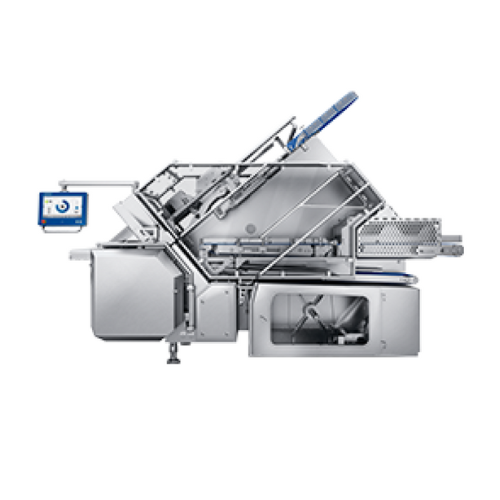

The Laska K 330-B cutter is equipped with a high cutting speed and 360° cutting impact that produces a fine emulsion with a consistent and high-quality product output. The low cutting gap of 0.8 – 1.3 mm between the blade and bowl of the machine improves accuracy, resulting in precise and consistent cuts.

The clear operating concept guarantees an optimal and transparent working environment making it easy to use and operate even for those with little experience. It has a low-maintenance and cost-effective design due to the use of a vibration-free blade shaft, bowl rotation, and AC drive technology. The newly engineered filtration system safeguards the commercial meat-cutting machine against dust, moisture, and vapour ingress, guaranteeing sustained longevity and dependable operational performance.