Print and Apply Label Applicators

Optimize your processes utilising Domino's flexible print and apply labeling systems. The MX350i-T, MX350i-S, and SP models are automated units designed for quicker production and minimizing manual errors.

Mx350i-T

The Mx350i-T case labeller enables precise labelling on various product surfaces and packages, whether contact (tamp) or non-contact (blow). Designed for industries such as food, beverage, life sciences, industrial, electronics, and logistics, it provides a robust, versatile, and user-friendly solution to meet high production demands.

- Left or right-hand variants

- 4-inch or 6-inch printers

- Position labels on the top, bottom, or side

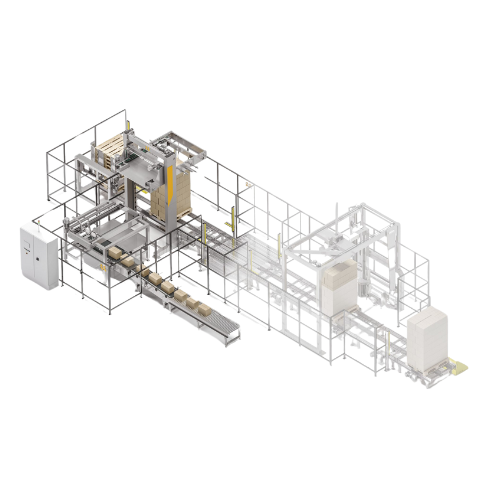

Mx350i-S&SP

The Mx350i-S and Mx350i-SP case labelling systems are ideal for high-demand productions in varying fields. Their three running modes allow them to print and apply labels to moving packaging from the top, side, corner, rear, or bottom for optimum performance and versatility.

- Left or right-hand variants

- 4-inch or 6-inch printers

- Flexible label positions

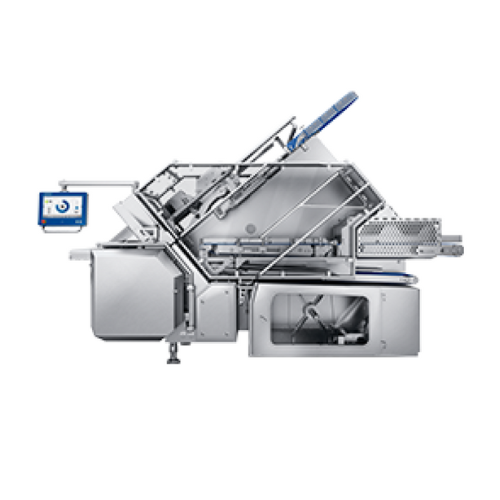

MX350i-DW

The Domino Mx350i-DW is a compact, cost-effective print-and-apply labelling solution ideal for straightforward applications. Its direct-wipe system allows precise labelling without compressed air, reducing costs and simplifying installation. Supporting variable data, it ensures high-resolution prints at up to 300 dpi.

- Left or right-hand variants

- Optional remote 10-inch touchscreen

- Seamless integration with ERP, WMS, and MES systems.

MX351i-EC

The Domino Mx351i-eC is an advanced print and apply solution for precise corner labelling on stationary packages. It supports high-resolution printing at 300 dpi, handles variable data, and integrates seamlessly with ERP systems. Its energy-efficient design reduces costs and environmental impact.

- Label placement: corner, front, or top of packages

- Supports 1D/2D barcodes, QR codes, logos, and text

- Reduces energy use by up to 80% compared to pneumatic systems